The Oxitrate cleaning and disinfection system effectively purifies process water and disinfects equipment and surfaces – with no need for chemicals. The system uses electrochemically activated water where the most important active substance is Hypochlorite acid. This removes all known bacteria, including Listeria and E.coli, from all stages of production. This ensures complete bacterial control and cleaner, safer and more environmentally friendly food and ice production.

Oxitrate is a scalable system, requiring only a single unit – regardless of the solution you choose. We offer everything from simple and affordable solutions to more advanced systems. Oxitrate is modular and consists of up to four modules. The system can also be integrated with existing solutions, such as CIP solutions and secondary washing stations.

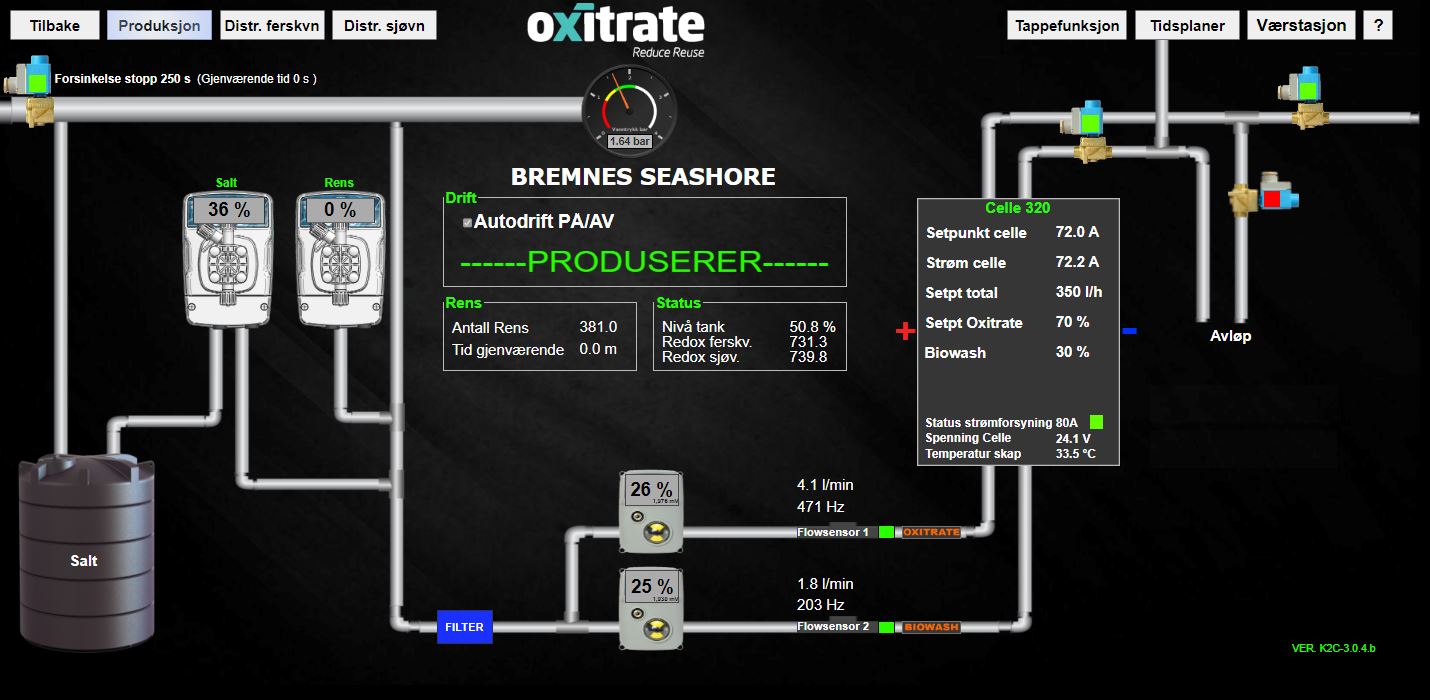

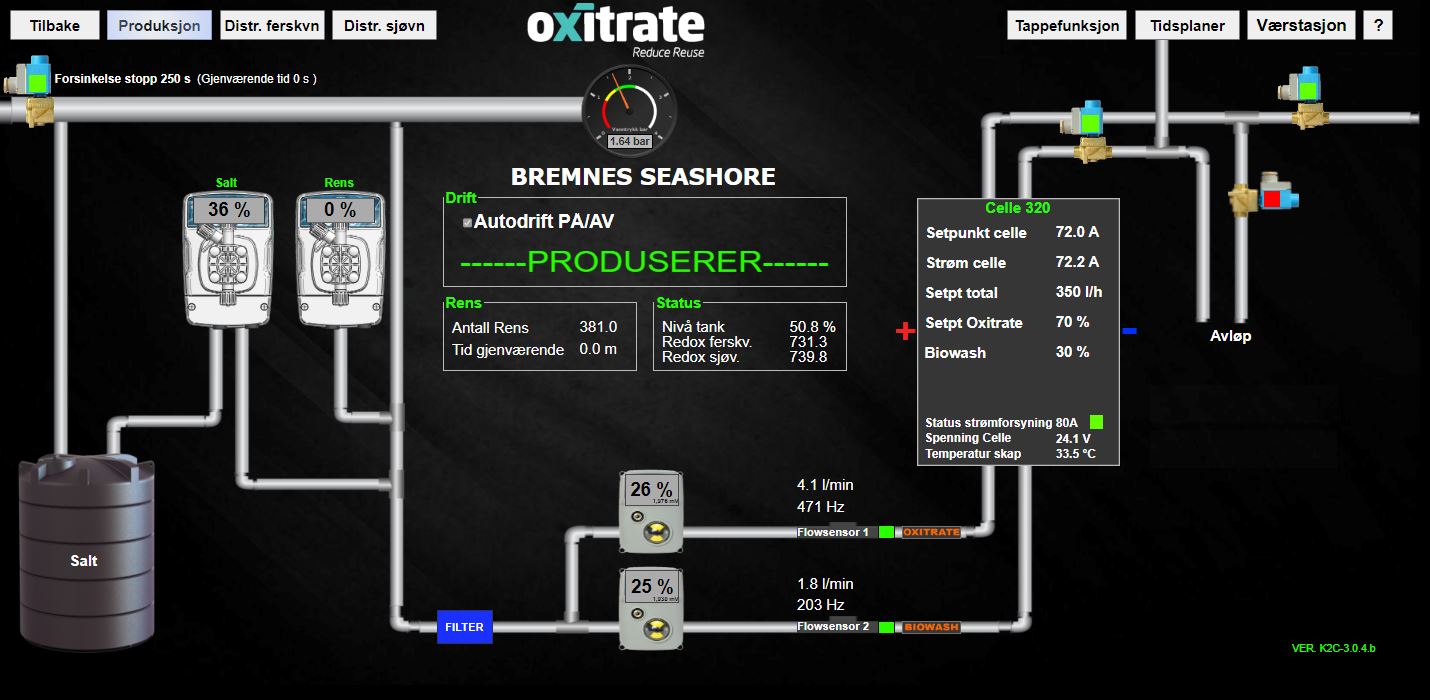

Oxitrate Insight gives you access to an advanced and user-friendly monitoring and control system that allows you to easily define the desired set points (e.g. redox level, pH value etc.) via a portal. Oxitrate Insight will then automatically manage your facility and notify you of any deviations.

Oxitrate Insight ensures that your desired values are achieved, regardless of the quality or volume of water. The system also serves as an effective reporting tool, continuously measuring various parameters – such as water and energy consumption – and generating reports that can be easily adapted to your needs.

Unique insight portal for water quality and reporting in the present

Using smart sensor technology, we are at the forefront of the industry by being able to offer an innovative insight portal that provides a complete overview of your facility’s water quality at all times, with real-time reporting.

Oxitrate Insight monitors all installations and has a warning system that ensures efficient system operation and monitoring. The portal provides real-time insight into water consumption and temperature, pH and redox values, among other features.

You can also generate your own insight reports, and the portal also offers employee training videos.

Oxitrate Basic is our main product. Oxitrate is automatically dosed into waterline(s) and will remove biofilm and ensure safe food production. Automated dozing in fresh water and seawater in the entire water flow creates a redox of +/- 700M. Oxitrate will also create a barrier which will be beneficial to unstable water supply from public facilities.

With Oxitrate Des you can disinfect surfaces, machines and other equipment after washing. Oxitrate Des is a powerful disinfection and you can mix or dispense the product as needed.

Oxitrate Biowash is an alkaline substance produced on site. Oxitrate Biowash replaces traditional cleaning chemicals, also when using secondary washing stations. Oxitrate Biowash offers great savings related to cleaning, in terms of both purchasing costs and energy consumption – not to mention time spent cleaning. ATP tests of Oxitrate Biowash shows RLU values between 0–6 (the maximum allowable RLU value for food production is 60).

Oxitrate Biowash CIP ensures you always have clean pipes. CIP (clean-in-place) is a method that automates the cleaning of surfaces and the inside of pipes, without needing to take them apart. Oxitrate disinfects the water, ensuring there is no bacteria in the water circuit. This means that no biofilm forms in the facility’s piping system.

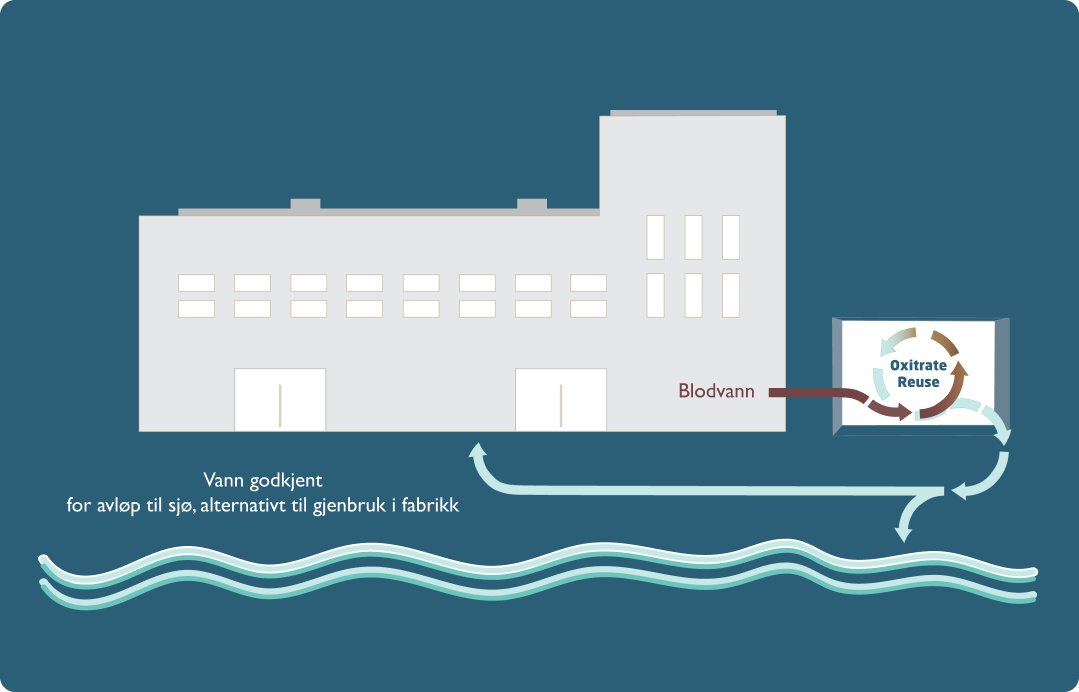

Oxitrate will soon be launching "Oxitrate Reuse," a new solution for treating process water in accordance with BAT-AEL (Best Available Techniques - Associated Emission Levels) requirements. Oxitrate Reuse is a container-based solution designed to separate the components in wastewater and subsequently purify the process water. The system contributes to reducing energy consumption and automatically addresses the challenge of process water and waste discharge. Additionally, this new solution aims to enable the reuse of significant volumes of the factory's process water.

Oxitrate Reuse will be a cost-effective option for meeting the new BAT requirements for the discharge of process water, meaning you won’t have to make large investments. Contact us today for more information.

We adapt our systems to customer needs and offer a service and maintenance agreement to ensure the best possible utilization of the facility.

Contact us

We installed our Oxitrate system in 2019 and since this time it has performed exceptionally well. We now have complete control of our process water, and we no longer have any issues with bacteria, such as Listeria. Oxitrate has also helped to streamline our washing process. We are constantly working to improve and we are now also expanding the Oxitrate system to be used in our dispensing system in the factory. This will allow us to replace many of the traditional and expensive chemicals we used to use.

– Per Johnny Bø, September 2022

COO, Sekkingstad

In November 2023, new EU requirements for emissions and waste management will be introduced for several industries, which will apply to Europe and Norway as a whole.

Read more »

We at Oxitrate have worked hard to further develop the user benefit of an installed system for all our customers. We are now launching extended use and benefits of your facility with three new areas of use beyond Oxitrate Dozing into waterline(s).

Read more »

New EU requirements for discharge of process water have consequences for Norwegian salmon slaughterhouses and fish reception.

Read more »