New purification requirements for the fishing industry

How should the industry meet the new requirements?

Oxitrate Reuse – is the solution

In November 2023, new EU requirements for emissions and waste management will be introduced for several industries, which will apply to Europe and Norway as a whole. The fishing industry is included in these new requirements, and efforts are now underway to apply for exemptions regarding the emissions directive and the accompanying BAT (Best Available Techniques) regulations from the EU. What will the new purification requirements mean for the fishing industry in Norway, and what solutions are available to meet these requirements?

The consequences for the food industry upon implementing the Industrial Emissions Directive (IED) are significant. The IED is an EU directive that has been implemented in Norwegian waste regulations through the EEA Agreement. This directive plays a crucial role in reducing pollution and ensuring fair competition conditions for industries in Europe. Based on the principle of Best Available Techniques (BAT), the IED requires companies to operate in compliance with the requirements set by the authorities in member states. These requirements include permit conditions based on BAT, which also encompass emission limit values. Permits are granted based on the overall environmental performance of the facility, including air, water, and land emissions, waste management, use of raw materials, energy efficiency, noise reduction, accident prevention, and site rehabilitation after the business is terminated.

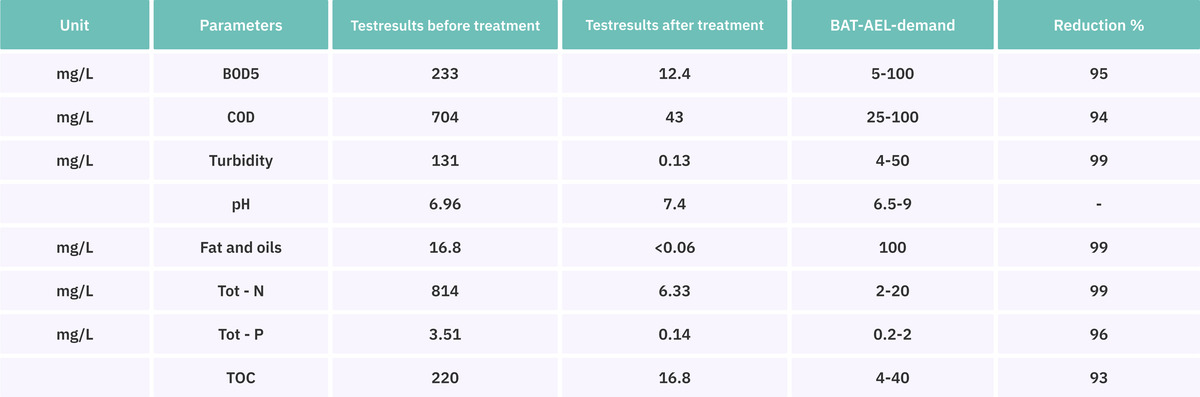

For the food industry, especially in fisheries, water emissions are of great importance. Many BAT conclusions specify that BAT-AEL (Best Available Techniques - Allowed Emission Level) for water emissions directly apply to discharges into a recipient, such as a river, lake, or sea. It is important to note that BAT-AEL values apply at the point where the discharge leaves the facility. This means that the industrial facility must implement appropriate techniques and measures to ensure that the emissions meet the prescribed BAT-AEL values before reaching the recipient. This requires efficient purification and advanced technologies to limit emissions and minimize environmental impact.

During the information meeting on BAT-AEL for water emissions in the food industry on June 3, 2021, it was clarified that all businesses under the IED must have an operating and emissions permit in accordance with the Pollution Control Act. Businesses that already have permits must have them revised with regard to BAT-AEL.

This means that the fishing industry has an independent responsibility to comply with BAT-AEL and limit its emissions. The industry must take measures to reduce its own emissions and comply with the requirements of the permit and the Pollution Control Act. Especially regarding process water emissions, purification must either take place within their own facility or at a public treatment plant that meets the new emission requirements. One of the significant consequences is that the industry will be required to purify more of its own wastewater or build its own treatment plants that meet the new emission requirements. This may entail significant investments and increased costs for the industry. Challenges also include land-use conflicts and the need for sufficient space to build their own treatment plants. To meet the BAT-AEL requirements, the industry must implement the best available techniques to reduce water emissions according to the BAT 12 form.

It is also worth mentioning that there may be temporary exemptions from the emission limits set in the directive in cases where they entail disproportionately high costs compared to environmental benefits. This may be related to the geographical location of the facility, local environmental conditions, or technical conditions of the facility. However, the exemptions are not permanent, as businesses are ultimately expected to comply with BAT-AEL at a later stage. Temporary exemptions can also be granted if the business has a plan to make process changes or establish and operate a new treatment plant.

In this context, Oxitrate Reuse can be a solution to help the fishing industry comply with BAT-AEL requirements in a more cost-effective manner. Oxitrate has developed a new innovative system called "Oxitrate Reuse," which aims to purify and reuse process water efficiently. By implementing this system, which is a container-based solution, it may be possible to meet the new BAT-AEL requirements while reducing emissions in a cost-effective way. The container solution solves land-use conflicts and the need for sufficient space to build their own treatment plant.

Image: Pump station 2/8

Image: Kera EKS filter 1-8

The system itself will be able to separate and purify the components in the fishery wastewater and then treat the process water in compliance with BAT-AEL requirements. Furthermore, Oxitrate Reuse employs a unique technology aimed at reusing significant volumes of the factory's process water, while also contributing to energy consumption reduction. This approach takes into account the overall environmental performance of the factory in a cost-effective and sustainable manner. By choosing Oxitrate Reuse, factories can avoid substantial investments required to meet the new BAT-AEL requirements.

Sources:

- https://www.miljodirektoratet.no/ansvarsomrader/forurensning/industri/for-naringsliv/industriutslippsdirektivet/veiledning-om-tema-i-bat-konklusjoner/

- https://www.statsforvalteren.no/siteassets/fm-oslo-og-viken/miljo-og-klima/forurensning/2021/informasjonsmote-naringsmiddelbransjen-3.-juni-2021-miljodirektoratet.pdf

- https://www.statsforvalteren.no/contentassets/28e8f731089247aabdfbab15ea52376a/informasjonsmote-naringsmiddelbransjen-3.-juni-2021---statsforvalteren.pdf